QUICK W5050-2S & W5050-2S+ Selective Soldering machine

New Generation Advanced Selective Soldering Equipments which are more Advanced than regular wave soldering and robotic soldering machines. Advanced Automatic Soldering machine.

In-line selective soldering machine with Dual pots.

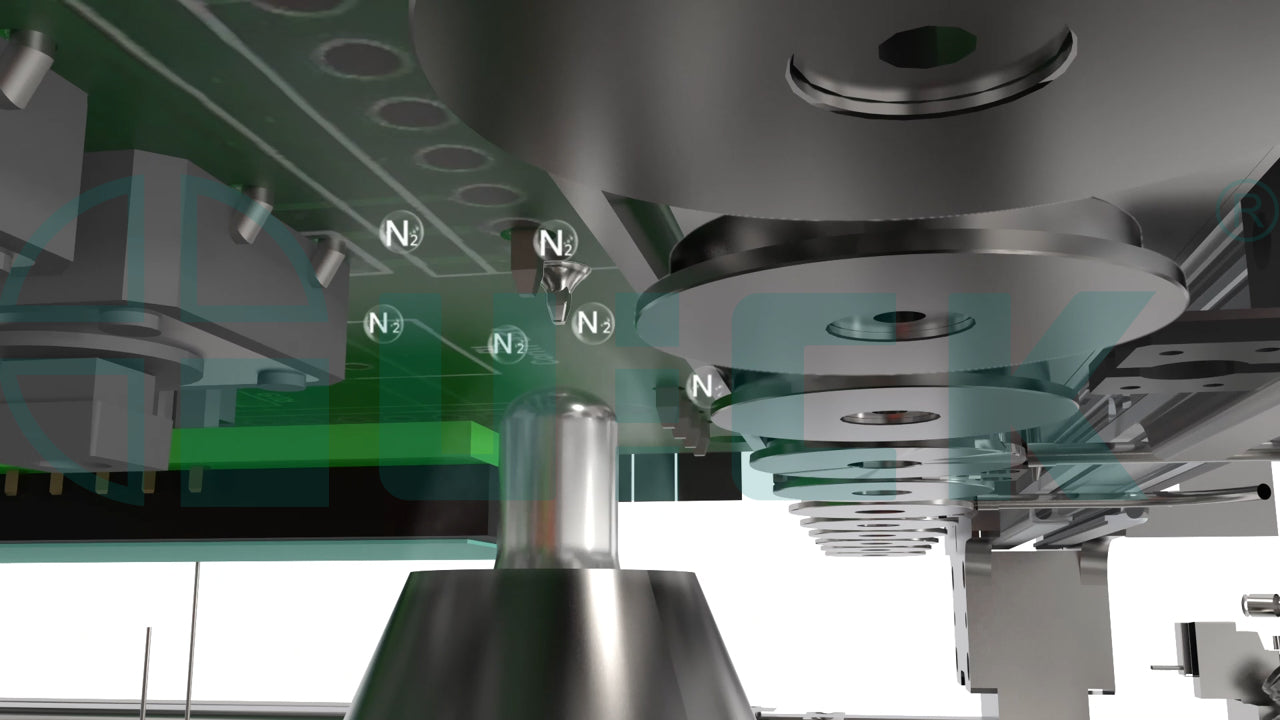

Dual pot synchronous Z Axis (W5050-2S) and Asynchronous Z Axis (W5050-2S+).

Faster and more efficient soldering which increases productivity.

Process includes Fluxing, Preheating & Soldering of selected points.

Features

W5050-2S double pot with single Z axis

W5050-2S+double pot with double Z axis

- Standard In-line machine with double-pot.

- Suitable for 508*508mm extra-large PCB production.

- Suitable for mass production of a single model.

- Fast programming, drawing soldering tracks based on pictures, simple and

efficient. - Intelligent vision system, automatic scanning, point identification and

correction, fool proof design. - Flux flow monitoring, liquid level monitoring, with a minimum coating width of 2mm, reduce PCB ion pollution.

- Online monitoring of preheating temperature, independent monitoring by the third party, safe and stable implementation of the heating system.

- Soldering temperature monitoring, wave peak monitoring, nitrogen

protection during the whole soldering process, greatly improves the

wettability and ensure the quality of soldering joints. - Electromagnetic pump used, constant flow, constant temperature, stable

wave height, no mechanical moving parts and free maintenance.

Two Different Nozzles in action

Selective Soldering machines with two same / different nozzles with Synchronous or Asynchronous Z axis movements. This increases productivity to a large extent.

Various types of Nozzles

Height and Diameter can be opted depending on requirement. Tall Nozzles can be used to solder in between large components. Wide Nozzles can be used to Solder multiple point at a time. This increases productivity and precision of Solder joints.

Why do we need Selective Soldering?

- To solder Components that cannot be soldered by wave soldering.

- Through – hole components that require high heat absorption.

- Needs to avoid high profiled components / Intricate places.

- Connectors that need high quality through hole soldering

- Soldering of extra long pins row plug components

- Capacitors and transformers and other components

- High quality and efficient soldering of large connectors

- Large joints

- Faster and Efficient production