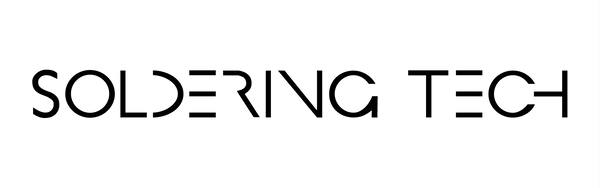

Automated Optical Inspection Machines

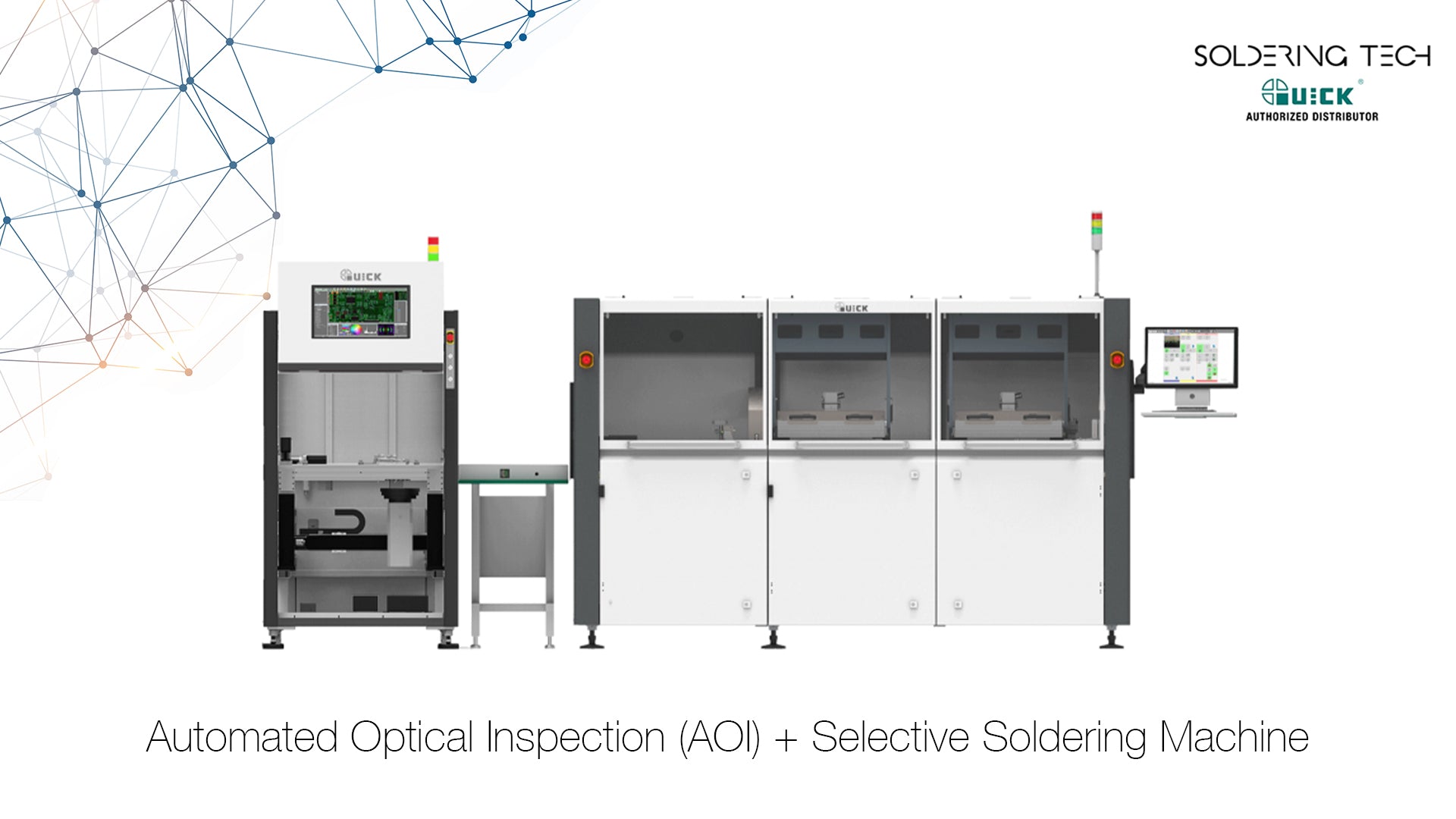

Optical inspection machines, particularly Automated Optical Inspection AOI are crucial for quality control in soldering processes.

AOI machines inspect PCBs after soldering for defects like component placement, missing components, and solder joint quality.

QUICK has Developed a wide range of Highly advanced 2D & 3D Optical Inspection machines with AI enabled features for more easier and reliable output.

These machines improve efficiency and reduce errors by automating inspection and providing data for process optimization.

This process includes loading the PCB, capturing images from various angles, pre-processing the images to enhance visibility, analyzing the images to identify defects, and then reporting the inspection 2D and 3D results.

Why do we need Automated Optical Inspection machines?

- Early defect detection : AOI can identify defects early in the manufacturing process, allowing for quick corrective actions and preventing the production of faulty boards.

- Improved quality control : By inspecting solder joints and component placement, AOI ensures that the assembled boards meet quality standards and are reliable.

- Cost savings : Identifying and correcting defects early reduces the cost of rework, scrap, and potential field failures.

- Enhanced efficiency : AOI systems are much faster than manual inspection, allowing for higher throughput in production lines.

- Data-driven optimization : AOI systems can provide data about the soldering process, which can be used to optimize the process and improve quality.

- Reduced human error : Automated inspection eliminates the variability and potential for human error in visual inspection.

AOI Models

-

QUICK EPOCH A300T 3D

SMT & Solder Joint 3D AOI (Top).

High-speed and high-precision, linear motor platform.

Advanced 3D reconstruction algorithm, reconstruct realistic 3D

information. With AI Programming. -

QUICK A200T & QUICK A200T-D

A200T - SMT & Solder Joint AOI (Top)

A200T-D - SMT & Solder Joint AOI(Top dual lane)

- Component Defects, Solder joint defects & Lead Defects

-

QUICK EPOCH A200B

SMT & Solder Joint AOI (Bottom)

Combineed AI with traditional algorithms, significantly increase inspection coverage. Bottom Detection - Component Defects, Solder joint defects & Lead Defects. AI algorithm capable of inspecting whole board solder bead, extra or damaged component & PCB scratches -

QUICK EPOCH A200

SMT & Solder Joint AOI

Top and bottom inspection at one time saving time and space. Combine AI with traditional algorithms, significantly increase inspection coverage. AI algorithm capable of inspecting whole board solder bead, extra or damaged component & PCB scratches

-

QUICK EPOCH A200TZ

SMT & Solder Joint AOI (Top) with

Z-axis design, compatible with products of different heights.

Combine AI with traditional algorithms, significantly increase inspection coverage. -

QUICK EPOCH A203TZ

SMT & Solder Joint AOI (Top) with

Z-axis design, compatible with products of different heights.

Combine AI with traditional algorithms, significantly increase inspection coverage.